As such, it is regarded as an industry metric that businesses can track to optimize processes and workflows, https://www.bookstime.com/ reduce lead times, measure work completed per time period, and identify bottlenecks. Work in process (WIP) inventory affects the cost of goods manufactured by adjusting for the unfinished goods at the beginning and end of the period. The beginning WIP is added to the total manufacturing costs incurred, while the ending WIP is subtracted. This ensures that only the costs of fully completed products are included in the cost of goods manufactured. Work in process is an asset account used to report inventory items not yet completed.

How Does WIP Inventory Affect the Cost of Goods Manufactured?

Work in process inventory plays an important role in production Liability Accounts and financial management. It represents partially completed goods that have incurred material, labor, and overhead costs but are not yet ready for sale. Proper tracking and management of WIP inventory ensure accurate financial reporting, improved production efficiency, and better resource allocation.

Managing Work in Process: Best Practices for Optimal Workflow

- Regionally, British English tends to favor ‘in progress’ in everyday contexts, while American English might see ‘in process’ used more frequently in formal documentation.

- If you want to apply G&A to COGS, the account with the COST GOODS SOLD Function Code must be included in the base of G&A.

- While ‘work in progress’ and ‘work in process’ are often used interchangeably, they can sometimes refer to distinct situations.

- These undertakings may take years to complete, and the financial benefits of work in progress projects may not be fully recognized within the next year.

- When a manufacturing order comes in and a forklift driver is sent to fetch the table legs and tabletops, these materials become part of the WIP inventory because they have met with labor.

- This differentiation may not necessarily be the norm, so either term can be used to refer to unfinished products in most situations.

- The formula for calculating work in progress inventory – in the specific context of a manufacturer – is as follows.

“In progress” should be used when something isn’t completed and is currently being worked on. WIP stands for “work in progress” and refers to any partially complete inventory not yet ready to be sold to customers. For smaller companies, a spreadsheet with columns specifying details like item information, quantity, material and production costs, production stage, and target completion date is the starting point. However, at the same time, WIP also flags potential issues in your production process, such as bottlenecks or delays.

Use a 3PL to help with inventory management

Our data and analytics dashboard is equipped with data to help your brand track inventory levels, fine-tune demand forecasting, set reorder points, and help you make better inventory decisions. Understanding WIP inventory can help you better understand supply chain management, so you can find ways to optimize your supply chain to drive more revenue. Once your WIP inventory turns into sellable goods, you will need a system in place to track inventory as it’s being sold. ShipBob’s technology fully integrates with your store to easily manage all inventory and orders from one central dashboard while they fulfill your orders on your behalf. WIP inventory accuracy ensures your financial statements reflect the true value of assets.

In the maintenance arena digital transformation refers to machine health monitoring systems and predictive maintenance solutions. Machine health monitoring involves instrumenting equipment with Industrial Internet of Things (IIoT) devices. Preventive work in process maintenance is important throughout manufacturing, but particularly at bottlenecks, predictive maintenance is a more effective strategy for reducing WIP.

Which Industries Commonly Use Work in Process Versus Work in Progress?

- Some organizations avoid the issue entirely by outsourcing any work that involves work-in-process inventory.

- Work in process inventory includes goods that are in production but not yet completed.

- In traditional manufacturing environments, inventory items move along a production line.

- “In progress” is more common in everyday conversation and can describe any activity that is currently happening.

- WIP levels have implications for both cash flow and operational efficiency.

If you recognize WIP G&A as a period cost, you can choose not to capitalize it when determining your net inventory balance. When it comes to inventory management, better insights mean better decisions. But in order to build the optimal inventory management system, you need the right tools. Correct tracking ensures accurate inventory valuation, which in turn leads to more reliable financial reporting and better decision-making. Regularly reviewing WIP enables you to catch potential quality issues early on.

- For example, a business might say a project is “in process” to indicate it is underway but not yet completed.

- This allows for better visibility and control over the production process, enabling timely interventions to address quality issues.

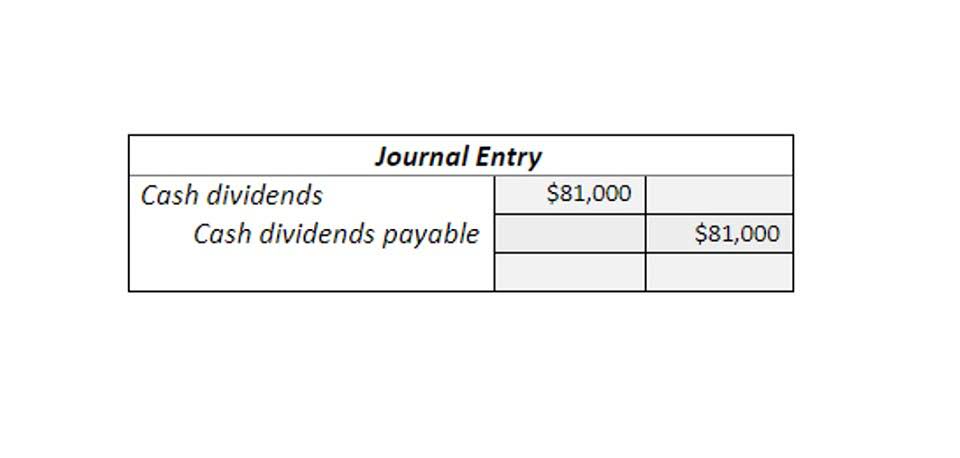

- On the income statement, the sale of the product would be recorded in the cost of goods sold (COGS) line item.

- This ensures that only the costs of fully completed products are included in the cost of goods manufactured.

Yes, “in process” is grammatically correct and is often used in legal, technical, or business contexts to describe procedures. You should use “in process” when describing a specific procedure or operational phase, often in formal or technical contexts. Having work that has yet to be completed will lower the number of items that are finished and delivered into production. WIP in process manufacturing is constrained in much the same way as on automated production lines. WIP in process industries is usually tracked at the batch level or in terms of quantity produced.

Get manufacturing know-how delivered to your inbox!

Understanding these subtle distinctions can enhance your communication skills and ensure the appropriate usage of these terms in various situations. AI is finding many roles in manufacturing, but one with significant WIP reduction potential is forecasting. With long supply chains, many manufacturers can’t wait for customer orders and instead release orders into the factory based on forecasts. AI can potentially improve forecasting, which will help with optimizing production schedules and managing bottlenecks. The answer for most businesses is to implement Lean manufacturing and just-in-time (JIT) production methods. This is best done in conjunction with lean maintenance techniques and ERP systems for real-time inventory tracking.

Significance of work in process in quality management

For instance, you might encounter it in phrases like “Your refund is currently in process,” emphasizing the procedural aspect. In the accounting system, WIP is listed as an asset, along with raw materials and manufactured goods. WIP inventory management helps manufacturers manage budgets, plan resources and meet accounting compliance standards.